Ford Announces Investment to Make Revolutionary Low-Cost, American-Built EV Family

The Chinese electric vehicles are here, and automakers are scared. They should be, too, because right now, you can buy an extraordinarily advanced, well-built, long-range, fast-charging Chinese-brand family EV outside the United States for a relative pittance compared to the average price of a new family car in the U.S. As a result, automakers are slowly starting to wake up to the legitimate existential threat, and Ford is the first to announce its specific strategy to fight back.

It’s been three years in the making, with a new platform, design and assembly method aimed at what is essentially an American EV moonshot. Can Ford make a truly inexpensive, fully competitive EV in the U.S. that would break through the social silliness surrounding EVs and put one in mainstream buyers’ driveways? It’s certainly going to try.

Related: Here Are the 11 Cheapest Electric Vehicles You Can Buy

The New Model T: Ford’s Universal EV Platform

- Ford’s new EV platform will underpin a family of affordable vehicles, beginning with a mid-size pickup truck in 2027.

- Ford will keep the new electric pickup’s price close to $30,000 by using fewer parts and optimizing the assembly process.

- The pickup will be a software-defined vehicle, and it will have a less expensive lithium-iron-phosphate battery integrated into the chassis to improve handling, interior space and noise.

There will be several elements to the new Ford EV revolution, the first of which being the vehicle itself. An all-new architecture called the Ford Universal EV Platform will spawn a family of affordable, fun-to-drive vehicles, starting with a mid-size electric pickup truck sometime in 2027. While the company isn’t ready yet to show the prototype truck, Ford has divulged a few key characteristics about the upcoming vehicle:

- It will have more interior passenger space than the latest Toyota RAV4, not including the truck bed and frunk.

- It will be as quick as a Mustang with the turbocharged EcoBoost four-cylinder engine.

- It will use a less expensive lithium-iron-phosphate battery, which Ford says will be first of its kind to be produced in the U.S. (other LFP batteries are imported mostly from China).

Most importantly, however, Ford says it is targeting a $30,000 price for this new mid-size electric pickup, which would put it well below the average price of a new vehicle in the U.S. (currently around $49,000) and in the ballpark of Ford’s own Mexico-built Maverick compact pickup.

How will Ford get the cost down so much? The company says it went back to the drawing board in all aspects of the design and construction of the vehicle, starting with what it is. The new platform has 20% fewer parts than a comparable modern vehicle and 25% fewer fasteners, resulting in 40% fewer workstations in the factory and a 15% faster assembly time. The platform will create a heavily software-defined vehicle — an industry term that describes a modern vehicle that uses independent computer-controlled subsystems to perform various tasks instead of a bunch of different components all connected by miles of complex, heavy wiring running through the vehicle.

For instance: Instead of requiring a dozen or more wires in a harness to each individual door from a central electronic control unit for the door’s locks, window controls, window motors, switches, speakers and more, a software-defined vehicle can have one computer module in that door connected to all of those things, with only one wire leaving the door and going to a central control module. Software, not direct wires to individual components, tells the module what to do. This means fewer and larger ECUs in a car, as well as less complexity for wiring, assembly and part numbers. This saves a lot of weight in the car and enables the automaker to continually improve the vehicle’s performance as code can be updated over the air as needed. Ford says the new pickup will have 4,000-feet less wiring in it than its first-generation electric SUV, the Mustang Mach-E, saving nearly 22 pounds of weight and material cost.

The new Ford Universal EV Platform will also integrate the battery pack into the vehicle’s chassis itself, using it as a structural subassembly. This will keep the center of gravity low for improved handling characteristics, free up interior space and improve interior noise. The battery pack will also supposedly be large enough to provide significant range or even power a standard family home for six days, according to Ford. The battery’s efficiency also will be dramatically improved, allowing Ford to use a battery that it says is one-third smaller than a conventional current lithium-ion pack, enabling lower costs for the vehicle overall.

More details and specifics of the vehicle itself are promised as it approaches production.

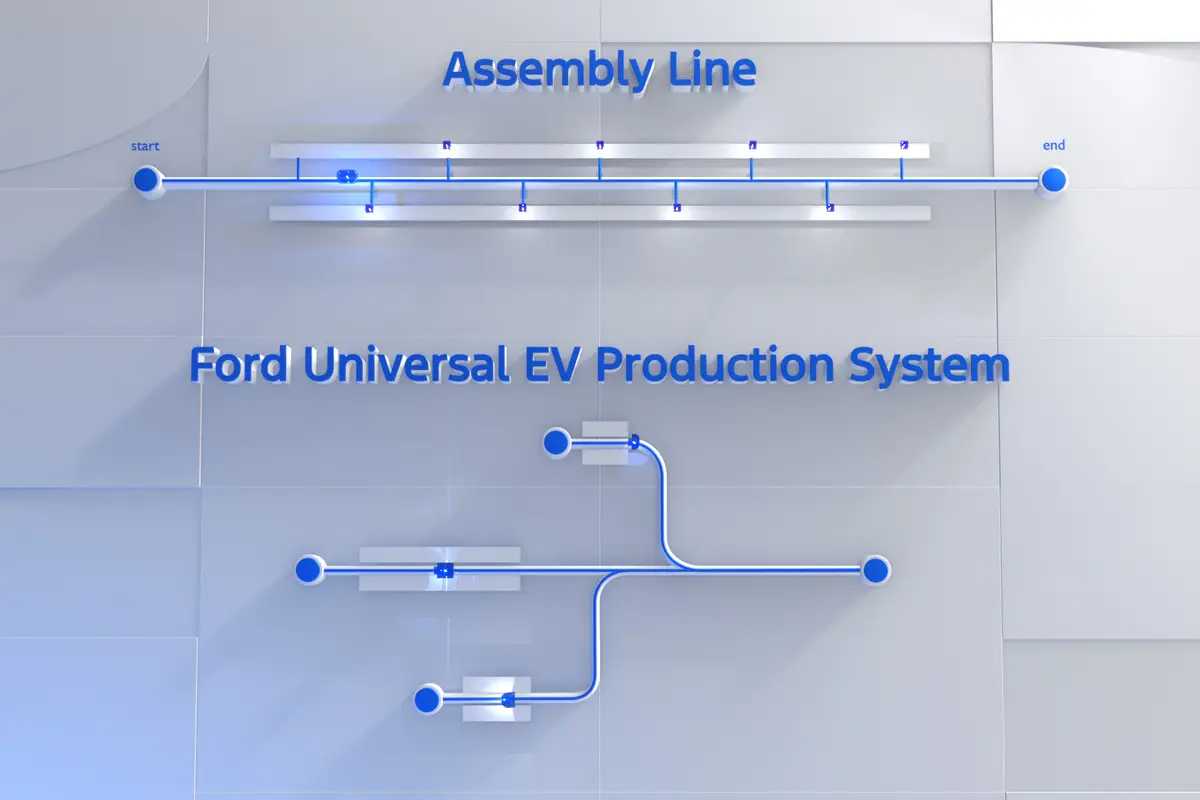

The Ford Universal EV Production System Builds It

- Ford reimagined the assembly process for the new EV platform to improve cost, productivity and throughput.

- The EVs will go down an “assembly tree,” with three sections being assembled at the same time and then joined in a final assembly station.

How the new Ford electric pickup truck (which some sources online have suggested will be called the Ranchero — how cool would that be?) is built will be just as important as the design of the thing in delivering that $30,000 price tag. Ford says it used a small skunkworks team in California to rethink the assembly process and has come up with a new method it feels will dramatically improve productivity, cost and throughput, abandoning the single-file assembly line idea and instead moving to more of an “assembly tree.”

The new pickup will be made in three pieces: a front assembly, rear assembly, and central battery assembly that also includes the body, interior and cabin structure. Each will be on a separate line and joined in a final assembly station. As Ford puts it, “large single-piece aluminum unicastings will replace dozens of smaller parts,” which sounds a lot like Ford taking a page out of Tesla’s Gigacasting process that’s used for the Cybertruck and other models. Workers will get parts in kits for each workstation in specific orientation to make assembly quick, simple and easy to perform.

The batteries will be made at BlueOval Battery Park Michigan. A $3 billion investment in that facility will be joined by a $2 billion expansion of Ford’s Louisville Assembly Plant in Kentucky, boosting jobs in both locations.

Read More About EVs:

- Electric Vehicles: Understanding the Terminology

- Your Guide to EV Batteries: Premature Death, Range Loss and Preservation

- Here Are the New Electric Vehicles Planned by 2027

- Electric Cars With the Longest Range

- What It Cost to Outfit 6 Homes With EV Chargers

- More EV News

Related Video:

Cars.com’s Editorial department is your source for automotive news and reviews. In line with Cars.com’s long-standing ethics policy, editors and reviewers don’t accept gifts or free trips from automakers. The Editorial department is independent of Cars.com’s advertising, sales and sponsored content departments.

Detroit Bureau Chief Aaron Bragman has had over 25 years of experience in the auto industry as a journalist, analyst, purchasing agent and program manager. Bragman grew up around his father’s classic Triumph sports cars (which were all sold and gone when he turned 16, much to his frustration) and comes from a Detroit family where cars put food on tables as much as smiles on faces. Today, he’s a member of the Automotive Press Association and the Midwest Automotive Media Association. His pronouns are he/him, but his adjectives are fat/sassy.

Featured stories

2025 Tesla Cybertruck Review: Wedge Issues

2026 Hyundai Palisade Review: Growing Gains